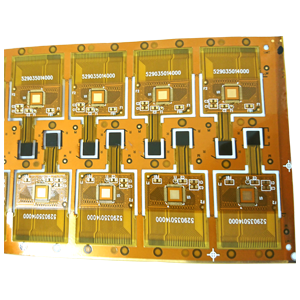

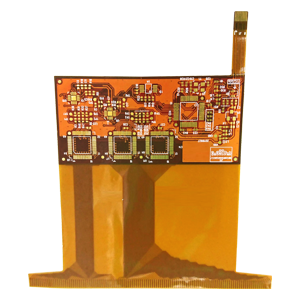

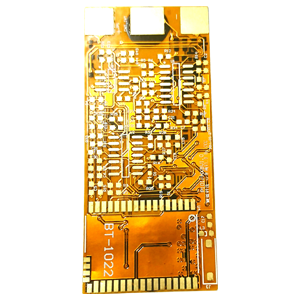

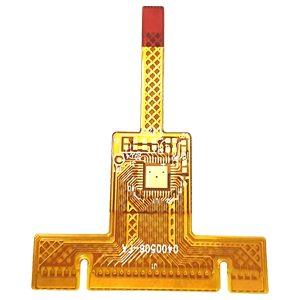

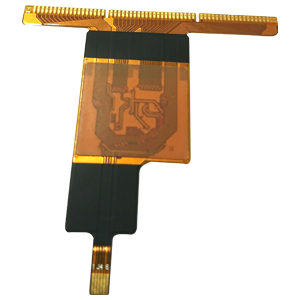

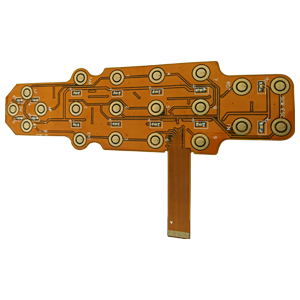

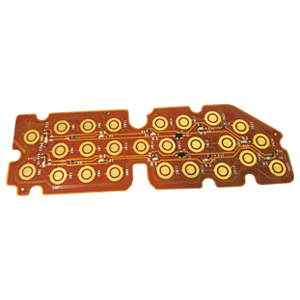

Flexible Printed Circuit (FPC) provides engineers much more options and flexibilities while designing circuits. The original purpose of designing FPC is replacing wire harnesses. Nowadays FPC are not only design for replacing wires, designers use FPCs to connect Rigid PCBs in order to fold a complex structure into limited space.

Types of FPC

- Single Side

- Single Side Double Access

- Double Side PCB

- Multilayers

- FPC with stiffeners

Benefit of FPC

- Higher circuit density

- Smaller product size

- Non planar surface assembly

- Dynamic purpose of use

- Improve impedance control performance

FPC Capability

| Feature | Capability | |

|---|---|---|

| Laminate | Laminate | 1-6 layers |

| Min. thickness | 2.5 mil(0.065 mm) | |

| Max working panel size | 300x500mm | |

| Copper Thickness | 0.33~3.0 oz (11~105um) | |

| Trace | Min. Line Width /Space | 2/2 mil |

| Dimension | Dimension tolerance | +/- 0.1 mm |

| Cover layer tolerance | +/- 0.5mm | |

| Mechanical drilling | Min. drilling hole size | 2 mil(0.05mm) |

| Max. aspect ratio | 10:1 | |

| Material Availability | PI, PET, PEN | |

| Finish Availability | Lead-free HASL, HASL, ENIG, Pattern Gold Plating, Immersion Silver/Tin, Carbon Ink | |